How to calculate TMT bar weight?

In modern construction, the TMT bar lays the foundation for the strength and durability of construction. The load-bearing capacity of reinforced structures plays a key role in the structural integrity of any construction. TMT bars are known as the “backbone” of any construction, as these bars hold a significant dead load of a structure, which is also referred to as the weight of the structure itself. Understanding the weight of the TMT bar is a significant aspect of design planning as it ensures the structure can withstand its weight without experiencing excessive deflection or structural failure.

The size of the TMT bar influences the weight of the bar. For instance, we produce TMT bars of Fe 550 grade, also known as UltraMax TMT bars, with a diameter range of 8mm to 32mm. As the diameter changes from 8mm to 32mm, the weight will differ. For a better understanding of how the size of the rebar impacts and how to calculate the weight of the TMT bar bundle, let’s get into the blog.

What is the process of calculating tmt bar weight?

If you purchase TMT bars for a new project, your contractor or engineer will recommend you purchase TMT bars in the bundle as per the size they recommended. The number of bars in the bundle will depend on the size and diameter of the TMT bar. This is why; the number of TMT bars in a bundle of 8mm, 12mm, 16mm, and 32mm UltraMax TMT bars will differ.

Let’s go over the calculation so you can have a better understanding of how to calculate the weight of the TMT bar:

If, the length of the TMT bar is in metres;

Formula for Weight of TMT Steel Bars Kg/Meter Length

W = (D² x L )/162 (Kg/m)

-

- D – Diameter of bar is measured in mm

- L – Length of bar is measured in meter

And, if the length of the TMT bar is in feet

Formula for Weight of TMT Steel Bars in Kg/ft

W = D² * L/533 (Kg/ft)

So, let’s take an example,

We are calculating the weight of a TMT bar whose length is 12m and the diameter is 8mm TMT bar

So, the weight will be after calculating from the formula mentioned above;

D= 8

L= 12

W= D2 L/162

W= 82 x12/162 = 4.74Kg

Understanding weight tolerance:

Each bundle of TMT bars must adhere to weight tolerance standards outlined in IS:1786-2008. These standards specify the allowable variation in weight for different sizes of bars, ensuring consistency and quality in construction materials.

Calculating Bundle Contents:

The table below illustrates the number of bars in each bundle if we take the standard length of the TMT bar as 12mtr, along with their approximate weights:

Size |

Pc/Bundle |

Approx Weight/Mtr |

Approx Per kg/ weight |

Length |

Approx Weight/Bundle |

| 8mm | 20 | 0.395 | 4.74 | 12 mtr | 94.8 |

| 10mm | 13 | 0.617 | 7.4 | 12 mtr | 96.2 |

| 12mm | 9 | 0.888 | 10.66 | 12 mtr | 95.9 |

| 16mm | 5 | 1.58 | 18.96 | 12 mtr | 94.8 |

| 20mm | 3 | 2.47 | 29.62 | 12 mtr | 88.86 |

| 25mm | 1 | 3.85 | 46.29 | 12 mtr | 46.29 |

| 28mm | 1 | 4.83 | 58.07 | 12 mtr | 58.07 |

| 32mm | 1 | 6.31 | 75.85 | 12 mtr | 75.72 |

How does the weight of the tmt bar influence the construction?

Structural stability

The weight of TMT bars directly impacts the structural stability of construction. Heavier bars have higher tensile strength compared to lighter ones, allowing them to withstand greater loads and stresses. This is why high-rise buildings or structures located in earthquake-prone areas prefer 32mm TMT bars over 8mm ones.

Transportation and material handling

The weight of TMT bars affects the ease of handling and transportation during construction. The weight of the bundle influences factors such as labor cost and the requirement for specialized equipment for lifting and positioning. For better handling and transportation, it is necessary to have almost the same weight in every bundle.

Foundation design

Weight plays an important role in building the foundation of construction. Heavy bars exert greater pressure on the underlying soil, necessitating thorough analysis and design consideration to prevent settlement or structural failure. Hence, engineers must carefully calculate the required weight of the TMT bar after soil analysis to ensure the integrity and structural stability of the construction.

Cost of construction

The weight of the TMT bar significantly impacts the cost of construction. Heavier bars typically cost more due to transportation costs and increased material usage. At Adukia, we have integrated modern technology and techniques, leading us to manufacture lighter-weight TMT bars. Let’s understand how the UltraMax TMT bar is different from standard steel bars in the market.

Adukia Industries UltraMax TMT bar;

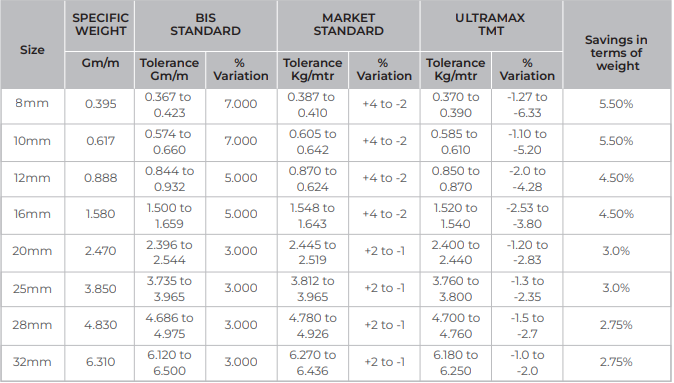

As you can see from the table above, the savings in terms of weight is significant if compared to market standard TMT bars.

Choosing strength, durability and stability with Adukia Industries UltraMax TMT bar

Opting for the right TMT bar grade and also weight is important for ensuring the stability and structural integrity of the construction project. With Adukia Industries, you get high-quality TMT bars which are manufactured with Thermax technology to offer lighter-weight TMT bars. By adhering to weight tolerance standards Adukia Industries addresses the key key concerns such as structural stability, transportation efficiency, foundation design, and overall construction costs. With a commitment to innovation and excellence, Adukia Industries continues to revolutionize the construction industry, providing solutions that prioritize safety, durability, and efficiency in every project.

Comments(4)

Leave a comment

Category

Recent Post

West Bengal’s Expanding Horizons: Exploring The Current TMT Bar Price In West Bengal

Mon July 2024

Top 10 TMT Bar Brands In India

Tue July 2024

Why Is Corrosion A Major Threat To Infrastructure? A Detailed Analysis of Corrosion Resistant TMT Bars

Fri July 2024

Where to get good quality TMT bars at the best price in Bihar?

Sat July 2024