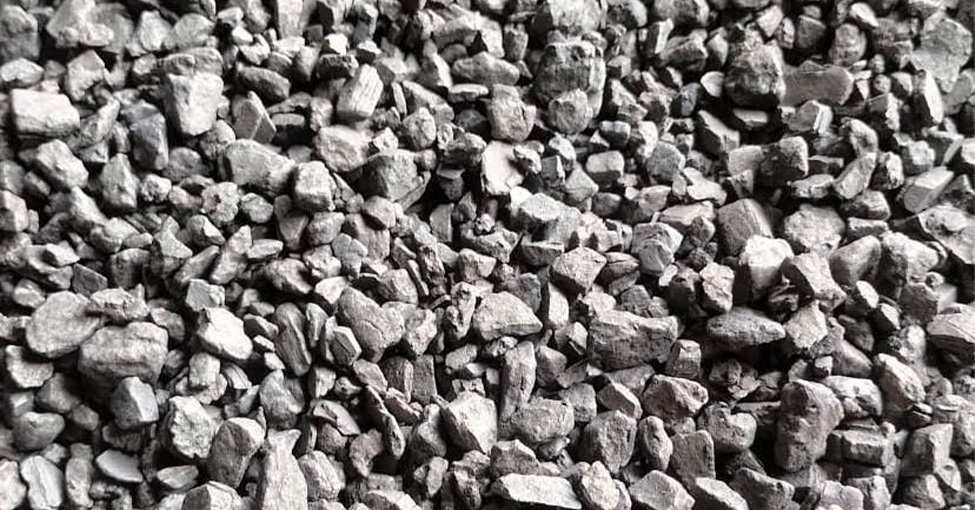

At Adukia Industries, we produce sponge iron through the direct reduction of iron ore using carbon in the form of coal at approximately 1100 degrees. This process results in the creation of metallic iron, which is also known as sponge iron, direct reduction iron (DRI), metalized iron, or hot briquetted iron.

Features

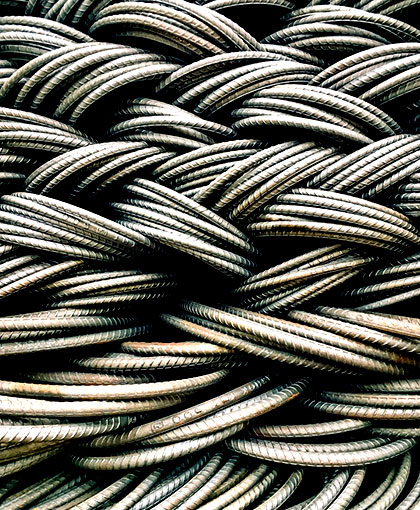

1. The high porosity (25-30%) of our product results in excellent reducibility.

2. The uniform size and spherical shape of our product provides excellent bed permeability.

3. Acid pellets are designed to have a high strength of 150-200 kg or more.

4. The heat consumption is significantly lower than that of sintering.

5. Our product features a high iron content and a uniform chemical composition, resulting in lower flux and fuel requirements for the furnace.

6. Our product has a low FeO content.

7. Our product is easy to handle.

8. Product boasts excellent levels of carbon and FeO, with particularly low levels of FeO. This makes it a highly desirable choice for steel mills utilizing DRI to reduce carbon, as the low FeO content offers a significant advantage in the carbon reduction process. This feature, combined with our product’s exceptional quality and low impurity levels, translates to improved efficiency in steel production.

9. Our pellet production process does not involve the use of lime, which means there is no wearing of the inner lining.

10. Material handling results in minimal dust generation.

11. Product has excellent flowability, ensuring continuous and trouble-free charging in bins, pipes, and conveyors.

Specifications

Chemical Properties:

| Constituent | Grade 1 |

| % Total Iron Fe(T) | 90 ± 2 % |

| % Mettalic Iron | 80 ± 2% |

| % Metallization | 88 ± 2% |

| % C | 0.10 – 0.25 % |

| % S,max | 0.03% |

| % P,max | 0.06 |

| % Gangue, max | 8 |

| SiO2 + AI2O3 | 6 % (max) |

| CaO + MgO | 1 % (max) |

| Size ( mm ) | 3 to 20 |

Physical Properties:

| Elements | Sponge Iron Lumps |

| Bulk Density (gm /cc ) | 1.8 |